Plastic panel repair replacement has become crucial in modern auto body repair due to vehicles' increasing use of lightweight, aesthetic plastic components. Skilled technicians use advanced tools and techniques to match exact vehicle specs, preserving structural integrity and original appearance. Integrating this service streamlines collision repair processes, reducing repair times and enhancing customer satisfaction. Effective implementation requires investment in high-quality tools, staff training, use of OEM parts, proper ventilation, and adherence to safety measures, making it a valuable service for auto body shops while meeting efficiency and quality standards.

In today’s automotive landscape, plastic panel repair and replacement (PPR) has emerged as a game-changer in collision repair. PPR offers a sustainable and cost-effective alternative to traditional metal repairs, aligning perfectly with modern environmental considerations. This article delves into the integration of PPR within collision repair processes, exploring its benefits and best practices for effective implementation. By understanding the intricacies of PPR, repair shops can enhance efficiency, reduce waste, and provide high-quality results.

- Understanding Plastic Panel Repair and Replacement: An Overview

- Integrating Plastic Repairs into Collision Repair Processes

- Benefits and Best Practices for Effective Implementation

Understanding Plastic Panel Repair and Replacement: An Overview

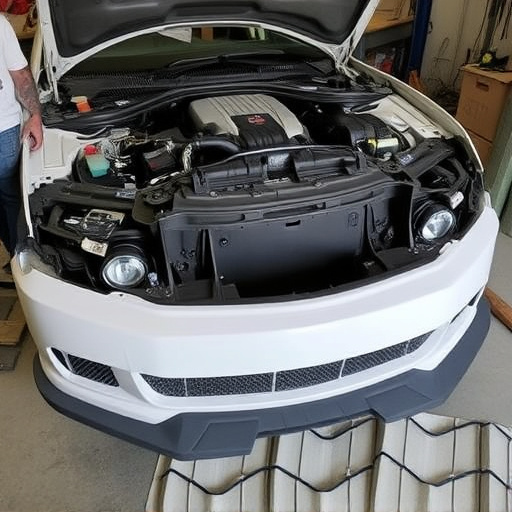

Plastic panel repair and replacement is a specialized service within the broader scope of auto body repair. With advancements in vehicle design often incorporating more plastic components for lightweight and aesthetic purposes, the need for efficient and precise repair methods has grown. This process involves the skilled manipulation of various types of plastics, from hard plastic panels to more flexible variants found in modern cars.

The integration of plastic panel repair replacement into collision repair services offers several advantages. It ensures that vehicles not only regain their structural integrity but also maintain their original appearance. Skilled technicians use advanced tools and techniques to match the exact specifications of the vehicle’s design, making repairs virtually indistinguishable from the original parts. This level of expertise is crucial in the auto body repair industry, as it guarantees customer satisfaction and preserves the value of the vehicle post-accident.

Integrating Plastic Repairs into Collision Repair Processes

Integrating plastic panel repair replacement into collision repair processes streamlines operations within automotive body shops. This advanced technique allows for more efficient vehicle restoration, ensuring that damaged panels are replaced with precise, custom-fit alternatives. By integrating this technology, auto body services can reduce repair times and enhance overall customer satisfaction.

In the realm of vehicle collision repair, plastic panel repair replacement offers a game-changer solution. Unlike traditional methods, which may involve lengthy painting or molding processes, modern techniques enable technicians to quickly restore damaged areas to their original condition. This not only expedites the repair process but also preserves the vehicle’s aesthetics and value, making it an increasingly popular choice among automotive body shops.

Benefits and Best Practices for Effective Implementation

The integration of plastic panel repair replacement into collision repair processes offers numerous advantages for both repair facilities and vehicle owners. One of the key benefits is the reduction in costs associated with complete panel replacements, which can be significantly more expensive than repairing or replacing individual components. By utilizing specialized techniques to fix or replace damaged plastic panels, auto body shops can minimize material waste, reduce labor times, and offer cost-effective solutions for various auto collision repair needs.

Effective implementation of this process requires adherence to best practices. These include investing in high-quality tools and training staff members on the latest plastic repair technologies. Utilizing original equipment manufacturer (OEM) parts ensures precision and longevity in the repair, maintaining the vehicle’s structural integrity and aesthetic appeal. Additionally, proper ventilation and safety measures should be in place, considering the potential fumes from certain repair materials. Auto body shops that embrace these practices can enhance customer satisfaction by delivering top-notch auto collision repair services, including efficient plastic panel repair replacement, thereby increasing their competitiveness in the market.

Plastic panel repair replacement is a game-changer in the collision repair industry, seamlessly integrating into existing processes to offer enhanced efficiency and cost savings. By understanding the techniques and best practices outlined in this article, shops can effectively incorporate these repairs, ensuring high-quality results while improving customer satisfaction. Embracing this innovative approach allows for a more sustainable and profitable future within the automotive sector.