Plastic panel repair and replacement is a meticulous process demanding skilled technicians to address various issues from accidents, weathering, or mechanical failures. It begins with a thorough inspection to identify damage, followed by preparation involving clearing debris and disassembling damaged parts if needed. Technicians use specialized tools like impact wrenches, heat guns, and autoclaves to restore panels to their original condition, ensuring both aesthetic appeal and structural soundness. Safety protocols, including PPE, are paramount throughout the process.

“Uncover the intricate art of plastic panel repair replacement—a crucial skill in the automotive or construction industries. This comprehensive guide delves into the step-by-step process, from identifying various types of plastic panel damage to mastering quality assurance. We’ll explore essential safety precautions and tools required, ensuring a seamless fix. Learn how to prepare damaged areas, accurately measure and cut new panels, and securely install them. Additionally, discover tips to avoid common mistakes and prevent future damage, empowering you with the knowledge for successful DIY repairs or guiding professional technicians.”

- Understanding Plastic Panel Damage and Preparation

- – Types of plastic panel damage

- – Safety precautions and tools required

Understanding Plastic Panel Damage and Preparation

Plastic panel damage can occur due to various reasons such as accidents, weathering, or mechanical failure, requiring skilled technicians for effective plastic panel repair replacement. Before initiating any repair work, a thorough understanding of the extent of the damage is crucial. Technicians begin by inspecting the affected area closely, identifying cracks, dents, or complete panel loss. This initial evaluation helps in determining the scope of the job and selecting the appropriate tools and materials.

Preparation is a vital step in achieving successful plastic panel repair replacement. The work area is typically prepared by clearing it of debris and ensuring proper lighting for precision work. In many cases, the technician might need to remove loose or damaged parts of the panel to gain access to the underlying structure. This involves using specialized tools to carefully disassemble the panel while taking precautions to prevent further damage, especially in the case of an auto bodywork collision.

– Types of plastic panel damage

Plastic panel damage can manifest in various forms, requiring technicians to be adept at diagnosing and repairing different types of car body repair issues. Common issues include dents, scratches, cracks, and breaks in the plastic components of a vehicle’s exterior. These damages can range from minor imperfections to significant structural compromises, necessitating precise techniques for plastic panel repair replacement. For instance, small dents might be addressed using specialized tools that smooth out the panel without affecting its integrity, while deeper damages may demand more extensive auto body work to ensure a seamless finish and optimal functionality.

Technicians employ a range of methods tailored to the extent and type of car damage repair needed. These can involve using heated tools for bending and shaping panels, precision cuts with specialized blades, or advanced techniques like injection molding for complex repairs. The goal is always to restore the plastic panel to its original condition, maintaining both aesthetic appeal and structural soundness, thereby enhancing the overall quality of auto body work.

– Safety precautions and tools required

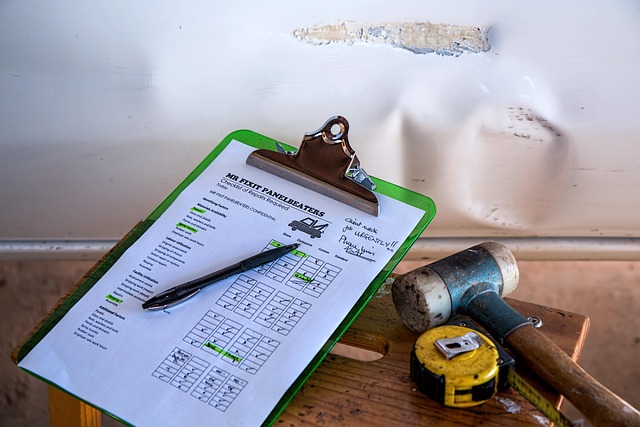

Before beginning any plastic panel repair or replacement, technicians must prioritize safety. This involves donning appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator to safeguard against hazardous materials and debris. The work area should be well-lit and organized to minimize the risk of accidents, with all necessary tools and parts within easy reach.

For effective plastic panel repair replacement, technicians require a specialized set of tools tailored for this process. This includes impact wrenches, screwdrivers, hammer, putty knives, and a heat gun for softening the existing panel. Additionally, an autoclave or vacuum degreaser might be needed to clean the area thoroughly, ensuring optimal adhesion for new parts. These tools, combined with expert skill and knowledge of auto collision centers, enable technicians to expertly restore damaged plastic panels, enhancing the vehicle’s aesthetics and structural integrity through top-quality auto repair services.

In conclusion, efficient plastic panel repair and replacement is a meticulous process that requires a deep understanding of damage types and adherence to safety protocols. Technicians must be adept in preparing surfaces and selecting suitable materials to ensure structural integrity and aesthetic restoration. By following systematic steps and utilizing the right tools, professionals can expertly navigate the challenges of plastic panel repair, providing long-lasting solutions for various vehicle damages.